Flat Beer? You Need Emergency Management Planning

It’s hard to fathom going to a bar for a drink and being served ‘flat’ beer – even in the UK! Worse still imagine being unable to go to hospital to have a medical procedure. And yet, this amazing situation is currently playing out in the UK and perfectly demonstrates why you need emergency management planning because comprehensive planning is the only way to deliver resilience in supply chains.

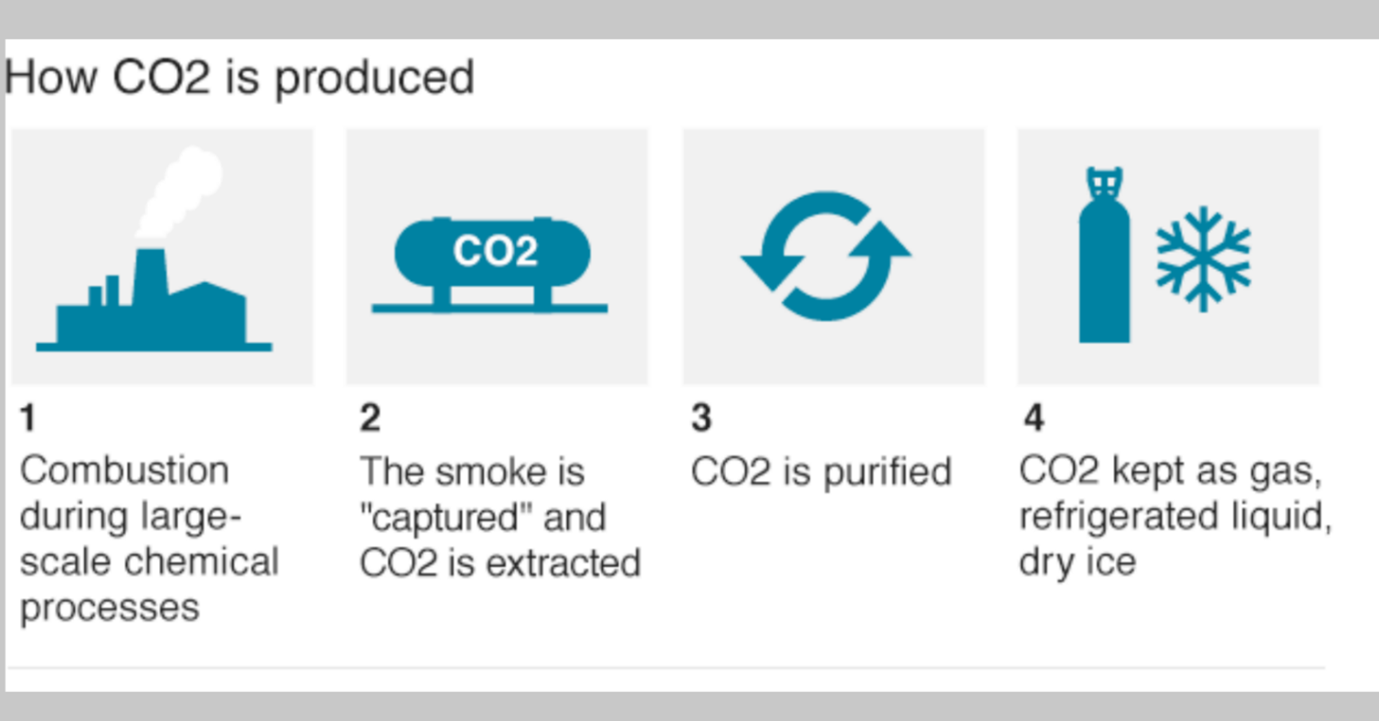

Carbon Dioxide (CO2) is an important additive in the food, beverage and health industries. It is used widely, for example, in the carbonisation of water, soft and alcoholic drinks; It is also used to stun pigs and chickens before they are humanely processed through abatoirs; It used in many medical procedures for humans too and it is used during packaging of a variety of supermarket foods to ensure extended shelf life.

In the UK, the current shortage of carbon dioxide has come about because two large fertiliser factories have stopped production because of soaring wholesale gas prices. Fertiliser plants generate CO2 as a by-product of their production process. The result? A 60% reduction in the UK’s food grade carbon dioxide supply.

The reduction in CO2 supplies has caused such shortages in the availability of a range of products that it has required intervention at a national government level. It is a remarkable situation and one that is proving difficult to resolve because the situation has arisen due to a fall in demand for fertilisers, not a fall in demand for carbon dioxide itself. The crisis has drawn attention to the fractured responsibility that exists in the supply chain and its management. Politically the issue lies across many areas of government.

Interestingly, this is not the first time a crisis involving the supply of Carbon Dioxide has occurred. It tends to be a cyclical event caused by a decrease in the production of fertiliser over the summer period. In 2018 a similar situation was reported. So, this incidence is entirely predictable and should have been resolved by proper emergency management planning to ensure resilience in the supply chain.

It is a great learning opportunity for all of us. All businesses need to ensure they have identified weaknesses and potential emergency situations and planned accordingly to deliver business continuity. Planning is the key to building resilience into systems and businesses.

The global pandemic has introduced a new normal to this equation. There’s more volatility, uncertainty, complexity, and ambiguity in our everyday lives, so we need to plan better for the unexpected. This requires a change in mindset and thinking. It requires businesses to perform detailed risk planning to identify vulnerabilities and adopt controls to ensure supply and operations.

Through Covid a key learning has been on the very issue the UK CO2 crisis illustrates – security of supply chains to ensure a business can continue to operate. There are many current examples where a lack of foresight has been exercised and businesses have been exposed. The automotive sector is a great source of learning along with many of our iconic parcel and package delivery services that have had to adjust their services due to unprecedented demand.

The learnings from the UK case study and Australia’s Covid experiences across a range of sectors make it abundantly clear that all businesses need to adapt quickly based on good data, intelligence, and evidence, leading to prompt decision making and the establishment of a rapid deployment capability.

It is an ever-changing world with new challenges and opportunities for businesses. Nuffield Group has the expertise and experience to support businesses in their risk assessment and emergency management planning.

Find out more:

contact us via the form on this website; email us direct at nuffield@nuffieldgroup.com or call 1300 308 257 or +61 404 852 062

Photo by Josh Olalde on Unsplash

Photo by Josh Olalde on Unsplash camilo-jimenez-vGu08RYjO-s-unsplash

camilo-jimenez-vGu08RYjO-s-unsplash Photo by Elisa Ventur on Unsplash

Photo by Elisa Ventur on Unsplash